Grade

600MPa:WDB620(Wuyang standard), SX610CF(China Three Gorges Corp. standard)

800MPa:WSD690(Wuyang standard), SX780CF(China Three Gorges Corp. standard)

Specs

Thickness(8~150)mm, Width(1500~3600)mm, Length(3000~16000)mm

Chemical composition (Melting analysis,%)

|

| Chemical composition* % (Quality score) |

|

|

Grade | Thickness |

| (mm) | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | V | B |

600MPa | ≤ | ≤ | ≤0.40 | 1 | ≤ | ≤ | ≤ | 0.15 | ≤ | ≤ | ≤ | ≤ |

80 | 0.07 | ~ | 0.015 | 0.005 | 0.5 | ~ | 0.5 | 0.3 | 0.05 | 0.003 |

>80 | ≤ | 1.6 |

|

|

| 1.5 |

|

|

|

|

~ | 0.09 |

|

|

|

|

|

|

|

|

|

≤120 |

|

|

|

|

|

|

|

|

|

|

>120 | ≤ | ≤0.40 | 1 | ≤ | ≤ | ≤ | 0.5 | ≤ | ≤ | ≤ | ≤ |

~ | 0.1 | ~ | 0.015 | 0.005 | 0.6 | ~ | 0.5 | 0.3 | 0.05 | 0.003 |

150 |

| 1.6 |

|

|

| 1.6 |

|

|

|

|

800MPa | ≤ | ≤ | ≤ | 0.7 | ≤ | ≤ | ≤ | 0.5 | ≤ | ≤ | ≤ | ≤ |

80 | 0.09 | 0.5 | ~ | 0.015 | 0.005 | 0.6 | ~ | 0.7 | 0.5 | 0.05 | 0.004 |

>80 | ≤ |

| 1.5 |

|

|

| 1.5 |

|

|

|

|

~ | 0.1 |

|

|

|

|

|

|

|

|

|

|

≤120 |

|

|

|

|

|

|

|

|

|

|

|

>120 | ≤ | ≤ | 0.7 | ≤ | ≤ | ≤ | 0.8 | ≤ | ≤ | ≤ | ≤ |

~ | 0.11 | 0.5 | ~ | 0.015 | 0.005 | 0.7 | ~ | 0.7 | 0.5 | 0.05 | 0.004 |

150 |

|

| 1.5 |

|

|

| 1.8 |

|

|

|

|

The supplier may add other elements to improve the plate performance with the content indicated in the quality certificate. |

Smelting analysis of carbon equivalent(%)and Pcm(%)

|

| Ceq% | Pcm% |

|

|

Grade | Thickness (mm) |

600MPa | ≤80 | ≤0.44 | ≤0.20 |

>80~≤120 | ≤0.46 | ≤0.23 |

>120~150 | ≤0.48 | ≤0.24 |

800MPa | ≤80 | ≤0.52 | ≤0.25 |

>80~≤120 | ≤0.54 | ≤0.26 |

>120~150 | ≤0.56 | ≤0.28 |

a Ceq=C+Mn/6+Si/24+Ni/40+Cr/5+Mo/4+V/14 |

|

b Pcm=C+Si/30+Mn/20+Cu/20+Ni/60+Cr/20+Mo/15+V/10+5B |

Mechanical and technological properties

| Grade |

| Yield strength | Tensile strength | Elongation b | Impact absorption energy |

| Impact energy c absorption after 5% strain aging | Cold-formed |

|

| Rp0.2 | Rm | A | ℃ | KV2 | ℃ | KV2 | α=1800 |

|

| MPa | MPa | % |

| J |

| J | b=2a |

|

|

|

|

|

|

|

|

| D=3a |

| 600MPa | ≤80 | ≥490 | 610~750 | ≥17 | -20 | ≥100 | -20 | ≥100 | No crack on the outer surface |

| >80~ | ≥470 | 590~730 | ≥17 | -20 | ≥100 | -20 | ≥100 |

| ≤120 |

| >120 | ≥450 | 570~730 | ≥17 | -20 | ≥100 | -20 | ≥100 |

| ~150 |

| 800MPa | ≤80 | ≥690 | 770~930 | ≥15 | -40 | ≥100 | -20 | ≥100 | No crack on the outer surface |

| >80~≤120 | ≥670 | 750~920 | ≥15 | -40 | ≥100 | -20 | ≥100 |

|

| >120 | ≥650 | 740~900 | ≥15 | -40 | ≥100 | -20 | ≥100 |

| ~150 |

| a It should be specified in the contract if Buyer shall specify the Z-direction performance which shall comply with the provisions of GB/T 5313. |

| b A (δ5) represents the elongation at break when LO=5.65SO0.5, where L0 is the original gauge length and S0 is the original cross-sectional area. |

| c The table shows the impact absorption energy index of the steel plate. The impact absorption energy at the corresponding temperature of the welded joint is ≥47J. The test result is calculated according to the arithmetic mean of the three samples. One of the sample values is allowed to be lower but not less than 70% of the specified value. |

600MPa Steel plates for hydropower

Chemical composition (Melting analysis,%)

Heat No. | C | Si | Mn | P | S | Ni | Cr | Cu | Al | Mo | V | Nb | Ceq | Pcm | Thickness |

|

15407611N3 | 0.06 | 0.19 | 1.55 | 0.01 | 0.002 | 0.23 | 0.23 | 0.16 | 0.031 | 0.22 | 0.038 | 0.017 | 0.4357 | 0.19 | 32-60 |

15408120N3 | 0.06 | 0.19 | 1.57 | 0.008 | 0.002 | 0.23 | 0.21 | 0.16 | 0.032 | 0.23 | 0.041 | 0.019 | 0.4378 | 0.19 | 32-70 |

15104022N0 | 0.07 | 0.18 | 1.3 | 0.008 | 0.002 | 0.41 | 0.34 | 0.17 | 0.015 | 0.29 | 0.042 | 0.019 | 0.4479 | 0.2 | 110-115 |

15104225N0 | 0.07 | 0.19 | 1.31 | 0.006 | 0.002 | 0.42 | 0.34 | 0.16 | 0.024 | 0.29 | 0.043 | 0.017 | 0.4503 | 0.2 | 90-100 |

15105180N0 | 0.08 | 0.15 | 1.2 | 0.006 | 0.001 | 0.42 | 0.36 | 0.21 | 0.025 | 0.28 | 0.045 | 0.022 | 0.442 | 0.2 | 110 |

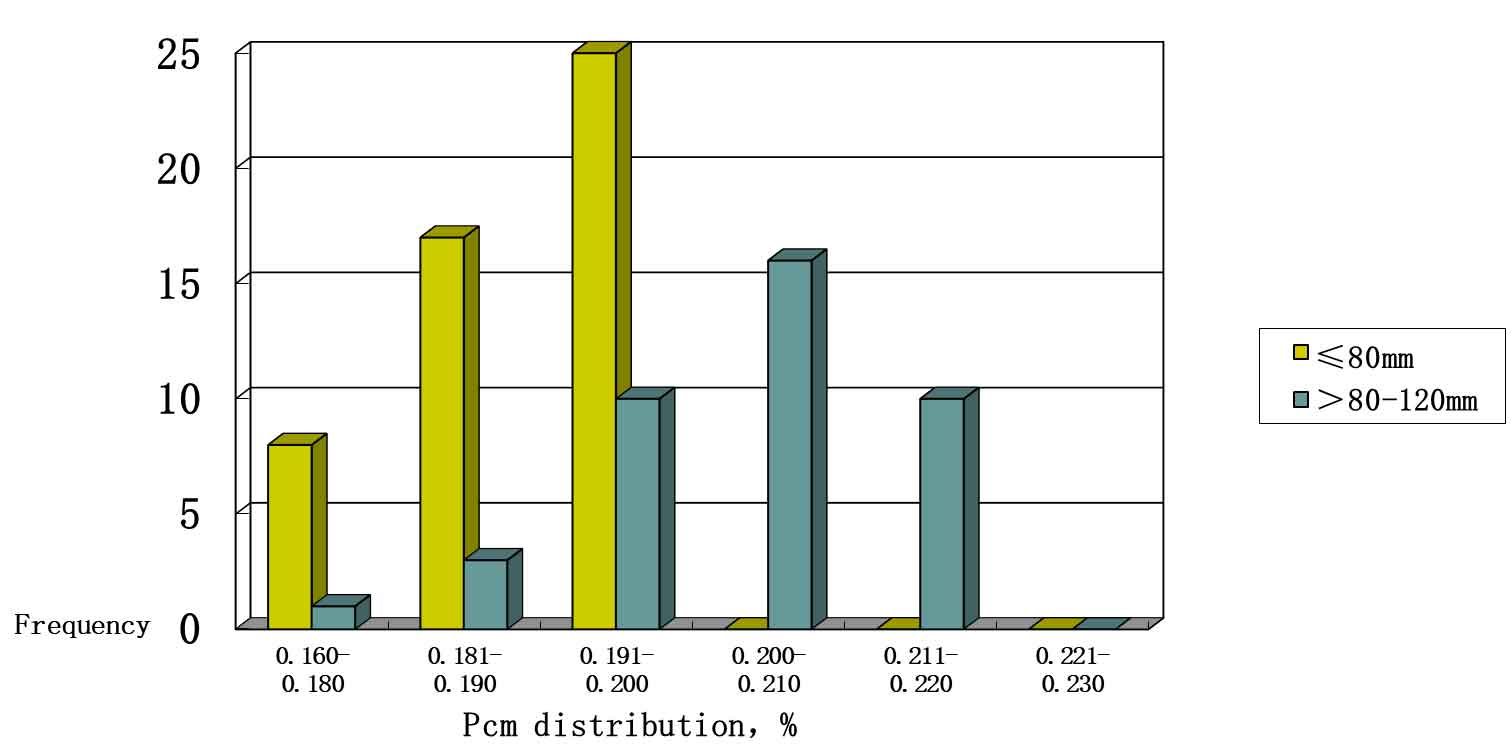

Product analysis of SX610CF Pcm distribution

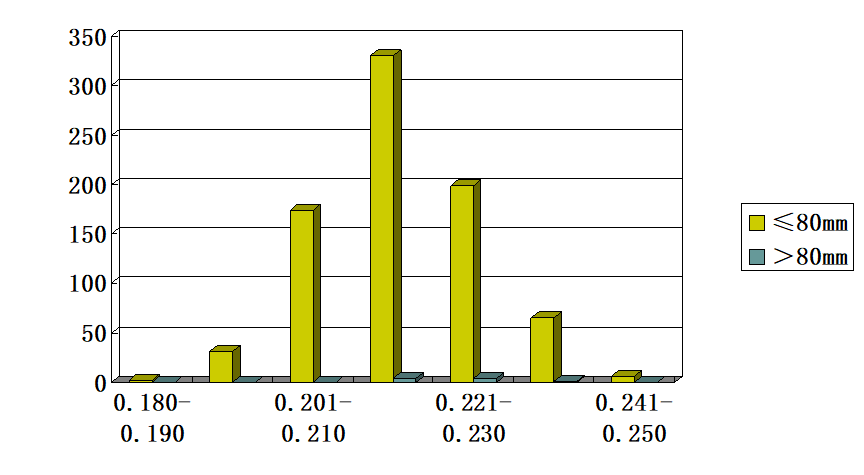

Product analysis of SX610CF Ceq distribution

Mechanical properties

Lot No. | Specs | Heat treatment | Yield strength | Strength | Elongation | Direction1 | -20℃ impact | Direction2 | Impact value 1 | Impact value 2 | Impact value 3 |

|

|

GZA521708 | 32 |

|

|

|

| horizontal | 248 | 263 | 268 | vertical | 380 | 376 | 359 |

GZA521708 | 32 | simulated post-weld |

|

|

| horizontal | 270 | 291 | 287 |

|

|

|

|

GZA521708 | 32 |

| 600 | 677 | 21 | vertical | 299 | 294 | 279 | horizontal | 343 | 324 | 313 |

GZA521708 | 32 | simulated post-weld | 581 | 662 | 21.5 | vertical | 299 | 297 | 291 |

|

|

|

|

GZHA514311 | 45 |

|

|

|

| vertical | 289 | 253 | 297 | horizontal | 359 | 368 | 363 |

GZHA514311 | 45 |

| 576 | 657 | 20 | horizontal | 273 | 295 | 299 | vertical | 359 | 373 | 370 |

GZHA514311 | 45 | simulated post-weld | 562 | 649 | 21 | vertical | 238 | 287 | 281 |

|

|

|

|

GZHA514311 | 45 | simulated post-weld |

|

|

| horizontal | 296 | 263 | 299 |

|

|

|

|

GZHA514254 | 60 |

| 549 | 633 | 21.5 | vertical | 293 | 267 | 246 | horizontal | 318 | 348 | 325 |

GZHA514254 | 60 |

|

|

|

| horizontal | 271 | 282 | 299 | vertical | 335 | 338 | 338 |

GZHA514254 | 60 | simulated post-weld | 542 | 635 | 24 | vertical | 251 | 284 | 222 |

|

|

|

|

GZHA514254 | 60 | simulated post-weld |

|

|

| horizontal | 253 | 272 | 249 |

|

|

|

|

Lot No. | Specs | Heat treatment | Yield strength | Strength | Elongation | Direction | -20℃ impact | Direction

2 | Impact value 1 | Impact value 2 | Impact value 3 |

GZHA514253 | 90 |

| 555 | 638 | 22.5 | horizontal | 261 | 250 | 267 | vertical | 316 | 336 | 331 |

GZHA514253 | 90 |

|

|

|

| vertical | 240 | 279 | 296 | horizontal | 273 | 236 | 338 |

GZHA514253 | 90 | simulated post-weld | 542 | 644 | 21.5 | vertical | 295 | 298 | 300 |

|

|

|

|

GZHA514253 | 90 | simulated post-weld |

|

|

| horizontal | 299 | 221 | 237 |

|

|

|

|

GZHA513771 | 110 |

| 538 | 626 | 21.5 | horizontal | 299 | 287 | 265 | horizontal | 270 | 279 | 218 |

GZHA513771 | 110 |

|

|

|

| vertical | 269 | 245 | 260 | vertical | 241 | 298 | 297 |

GZHA513771 | 110 | simulated post-weld | 561 | 644 | 19.5 | horizontal | 245 | 250 | 264 |

|

|

|

|

GZHA513771 | 110 | simulated post-weld |

|

|

| vertical | 271 | 258 | 289 |

|

|

|

|

GZHA513773 | 110 |

| 504 | 617 | 21 | horizontal | 263 | 291 | 292 | horizontal | 245 | 277 | 272 |

GZHA513773 | 110 |

|

|

|

| vertical | 299 | 299 | 293 | vertical | 300 | 287 | 275 |

GZHA513773 | 110 | simulated post-weld | 547 | 647 | 19.5 | horizontal | 247 | 276 | 255 |

|

|

|

|

GZHA513773 | 110 | simulated post-weld |

|

|

| vertical | 268 | 268 | 271 |

|

|

|

|

700MPa Steel plates for hydropower

Chemical composition (Melting analysis,%)

Heat No. | C | Si | Mn | P | S | Ni | Cr | Cu | Al | Ti | Mo | V | Nb | B | Ceq | Pcm |

15408309N3 | 0.07 | 0.18 | 1.11 | 0.005 | 0.003 | 0.58 | 0.53 | 0.23 | 0.037 | 0.011 | 0.44 | 0.033 | 0.012 | 0.0009 | 0.4954 | 0.216 |

15408310N3 | 0.07 | 0.19 | 1.13 | 0.003 | 0.002 | 0.57 | 0.52 | 0.24 | 0.04 | 0.007 | 0.45 | 0.035 | 0.012 | 0.001 | 0.4995 | 0.219 |

15408311N3 | 0.07 | 0.17 | 1.16 | 0.005 | 0.003 | 0.59 | 0.52 | 0.25 | 0.04 | 0.012 | 0.44 | 0.031 | 0.009 | 0.0008 | 0.5014 | 0.218 |

15408312N3 | 0.07 | 0.19 | 1.13 | 0.003 | 0.001 | 0.58 | 0.52 | 0.26 | 0.022 | 0.006 | 0.43 | 0.031 | 0.01 | 0.0008 | 0.4945 | 0.217 |

15408660N3 | 0.07 | 0.19 | 1.14 | 0.01 | 0.002 | 0.55 | 0.54 | 0.23 | 0.041 | 0.012 | 0.43 | 0.031 | 0.01 | 0.001 | 0.4994 | 0.218 |

15408661N3 | 0.07 | 0.17 | 1.13 | 0.007 | 0.002 | 0.55 | 0.55 | 0.22 | 0.036 | 0.008 | 0.43 | 0.031 | 0.011 | 0.0008 | 0.4989 | 0.216 |

15408662N3 | 0.07 | 0.19 | 1.15 | 0.007 | 0.002 | 0.56 | 0.55 | 0.23 | 0.048 | 0.01 | 0.43 | 0.03 | 0.011 | 0.001 | 0.5032 | 0.219 |

15408733N3 | 0.07 | 0.14 | 1.15 | 0.006 | 0.003 | 0.57 | 0.54 | 0.22 | 0.035 | 0.006 | 0.43 | 0.032 | 0.01 | 0.0014 | 0.4995 | 0.219 |

15409496N3 | 0.08 | 0.16 | 1.17 | 0.007 | 0.003 | 0.56 | 0.54 | 0.21 | 0.029 | 0.005 | 0.45 | 0.032 | 0.01 | 0.001 | 0.5185 | 0.229 |

15409497N3 | 0.07 | 0.16 | 1.16 | 0.008 | 0.004 | 0.58 | 0.55 | 0.21 | 0.031 | 0.005 | 0.44 | 0.031 | 0.01 | 0.001 | 0.5067 | 0.218 |

15409742N3 | 0.07 | 0.13 | 1.15 | 0.008 | 0.002 | 0.57 | 0.56 | 0.22 | 0.03 | 0.004 | 0.44 | 0.034 | 0.011 | 0.0008 | 0.5058 | 0.217 |

15409743N3 | 0.07 | 0.13 | 1.14 | 0.008 | 0.002 | 0.57 | 0.56 | 0.22 | 0.032 | 0.004 | 0.44 | 0.034 | 0.011 | 0.0008 | 0.5041 | 0.217 |

15409744N3 | 0.07 | 0.17 | 1.16 | 0.006 | 0.003 | 0.56 | 0.54 | 0.21 | 0.033 | 0.004 | 0.45 | 0.031 | 0.011 | 0.001 | 0.5071 | 0.219 |

15409886N3 | 0.08 | 0.12 | 1.15 | 0.004 | 0.002 | 0.56 | 0.55 | 0.21 | 0.031 | 0.006 | 0.43 | 0.035 | 0.01 | 0.001 | 0.5107 | 0.226 |

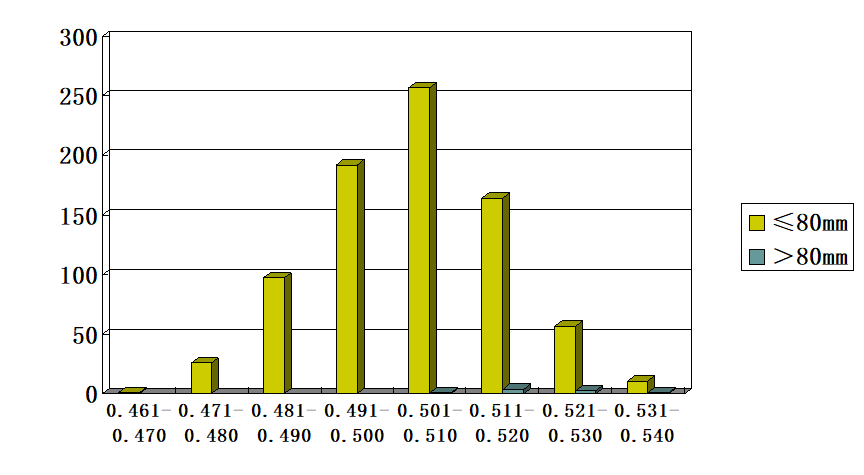

Product analysis of SX780CF Pcm distribution

Product analysis of SX780CF Ceq distribution

Mechanical properties

| Heat No. | Specs | Yield strength | Strength | Elongation | Impact | Impact value 1 | Impact value 2 | Impact value 3 | Impact | Impact value 1 | Impact value 2 | Impact value 3 |

| 15408310N3 | 56 | 794 | 836 | 17 | -40℃ | 232 | 211 | 252 | -20℃ | 306 | 295 | 314 |

| 15408311N3 | 56 | 797 | 842 | 18 | -40℃ | 256 | 190 | 241 | -20℃ | 258 | 301 | 249 |

| 15408312N3 | 56 | 774 | 825 | 18 | -40℃ | 216 | 239 | 237 | -20℃ | 175 | 243 | 235 |

| 15408660N3 | 60 | 801 | 840 | 20 | -40℃ | 258 | 200 | 227 | -20℃ | 273 | 269 | 288 |

| 15408662N3 | 60 | 763 | 821 | 18.5 | -40℃ | 261 | 260 | 258 | -20℃ | 198 | 253 | 278 |

| 15408663N3 | 60 | 788 | 847 | 19 | -40℃ | 211 | 199 | 208 | -20℃ | 254 | 268 | 259 |

| 15408698N3 | 60 | 776 | 821 | 18 | -40℃ | 284 | 253 | 274 | -20℃ | 210 | 210 | 173 |

| 15408700N3 | 60 | 784 | 837 | 18 | -40℃ | 252 | 283 | 259 | -20℃ | 261 | 268 | 251 |

| 15408733N3 | 60 | 775 | 821 | 17.5 | -40℃ | 237 | 268 | 248 | -20℃ | 305 | 366 | 308 |

| 15408736N3 | 60 | 793 | 835 | 18 | -40℃ | 165 | 176 | 190 | -20℃ | 260 | 266 | 270 |

| 15409305N3 | 56 | 770 | 816 | 17 | -40℃ | 206 | 211 | 196 | -20℃ | 288 | 304 | 261 |

| 15409306N3 | 56 | 767 | 825 | 19 | -40℃ | 240 | 271 | 250 | -20℃ | 346 | 301 | 330 |

| 15409307N3 | 56 | 780 | 832 | 19.5 | -40℃ | 200 | 204 | 241 | -20℃ | 304 | 269 | 331 |

| 15409496N3 | 60 | 747 | 817 | 18 | -40℃ | 236 | 235 | 260 | -20℃ | 271 | 331 | 249 |

| 15409497N3 | 60 | 751 | 817 | 20 | -40℃ | 164 | 168 | 175 | -20℃ | 195 | 218 | 245 |

| 15409743N3 | 60 | 778 | 836 | 17.5 | -40℃ | 282 | 300 | 284 | -20℃ | 291 | 193 | 229 |

| 15409744N3 | 56 | 765 | 832 | 19.5 | -40℃ | 260 | 299 | 153 | -20℃ | 258 | 346 | 318 |

| 15409886N3 | 56 | 767 | 827 | 19 | -40℃ | 190 | 152 | 199 | -20℃ | 230 | 285 | 314 |

Bending performance

To verify the cold bending formability of WSD690E plate, cold bending tests are carried out respectively on 60mm, 85mm and 100mm plates with four diameters of bending centers d=1.5a, d=2.0a, d=2.5a and d=3.0a.

The test results show that the surfaces of 60mm, 85mm and 100mm plates after cold bending are good. Thus, WSD690E plate has good cold bending formability.