Cogent Hi-Lite™ is the ultimate non-oriented ultra-thin gauge electrical steel. Its unsurpassed material properties enable the development of high-frequency applications with exceptional performance.

Loss at high frequencies, magnetization curve and strength are all important parameters for the design of high rotation speed machines. Cogent Hi-Lite™ offers a unique combination of these properties often exceeding similar grades from competitors.

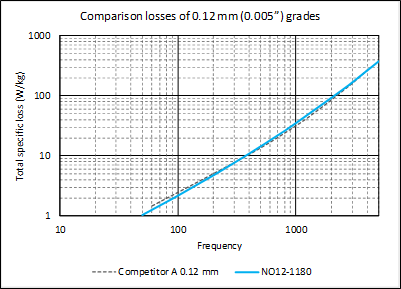

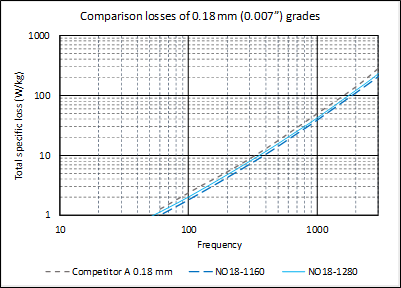

Typical loss of Cogent Hi-Lite™ in comparison with competitor A

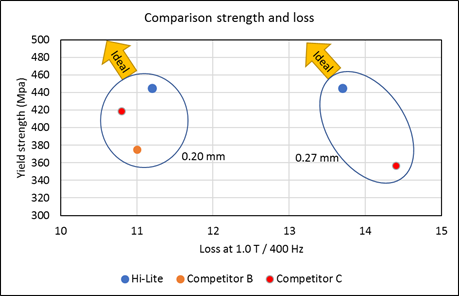

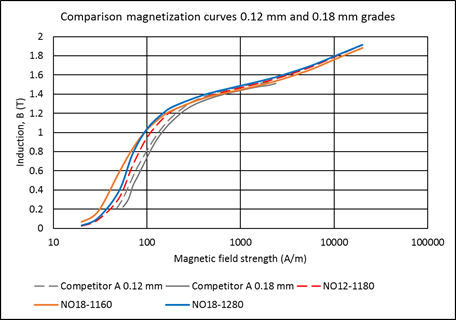

Typical magnetization curves of Cogent Hi-Lite™ compared Typical relationship between the strength and the high frequency loss for Cogent

to competitor A. Hi-Lite ™ compared with competitor B and C.

Cogent Hi-Lite Typical Properties |

Grade | Gauge | Losses at 1.0 T W/kg / W/lb | Jpeak at 5000 A/m | Yield strength |

mm / inch | 400 Hz | 1000 Hz | 2500 Hz | T | MPa / KSI |

NO10-1270N | 0.10 / 0.004 | 11.4 / 5.17 | 35.2 / 16.0 | 123 / 55.8 | 1.65 | 390 / 56.6 |

NO12-1180N | 0.12 / 0.005 | 10.9 / 4.94 | 35.9 / 16.3 | 131 / 59.4 | 1.66 | 390 / 56.6 |

NO15-1230N | 0.15 / 0.006 | 11.2 / 5.08 | 38.8 / 17.6 | 148 / 67.1 | 1.66 | 390 / 56.6 |

NO18-1280N | 0.18 / 0.007 | 11.9 / 5.40 | 43.4 / 19.7 | 171 / 77.6 | 1.67 | 390 / 56.6 |

NO20-1350N | 0.20 / 0.008 | 12.2 / 5.53 | 45.4 / 20.6 | 188 / 85.3 | 1.67 | 370 / 53.7 |

NO18-1160H | 0.18 / 0.007 | 10.6 / 4.81 | 39.2 / 17.8 | 157 / 71.2 | 1.64 | 445 / 64.5 |

NO20-1200H | 0.20 / 0.008 | 11.2 / 5.08 | 42.4 / 19.2 | 175 / 79.4 | 1.64 | 445 / 64.5 |

NO25-1350H | 0.25 / 0.010 | 12.5 / 5.67 | 49.5 / 22.5 | 214 / 97.1 | 1.64 | 445 / 64.5 |

NO27-1450H | 0.27 / 0.011 | 13.7 / 6.21 | 55.9 / 25.4 | 250 / 113 | 1.64 | 445 / 64.5 |

NO30-1500H | 0.30 / 0.012 | 14.1 / 6.40 | 58.6 / 26.6 | 270 / 122 | 1.64 | 445 / 64.5 |

Cogent Hi-Lite™ grades are offered with different Suralac™ coatings.

Suralac | Type | Thickness | Main characteristics |

7000 | C-5 | 0.7 µm, 30 µinch | High temperature, Annealable |

7000S | C-5 'punching' | 0.7 µm, 30 µinch | High temperature, Stampability |

9000 | C-3 'bonding' | 4.5 µm, 180 µinch | Bonding coating

|